Triaxial (TXC) testing is conducted to obtain elastic mechanical properties and the compressive strength of rock samples. When conducted on sample sets prepared at different orientations relative to bedding, it is used to define changes in elastic properties and strength as a function of orientation allowing for understanding of anisotropic behavior. When conducted on sample sets with a different confining stress per sample, the increase in strength (and elastic moduli) with increasing confining stress is used to define failure envelopes (e.g., Mohr-Coulomb).

Brazil Indirect Tensile Strength (BRZ) testing is conducted to obtain unconfined tensile strength of rock samples. Brazil tests at WDVGE are conducted on vertically oriented samples (with bedding parallel to the face of the plug) to minimize the effect of bedding on the stress distribution.

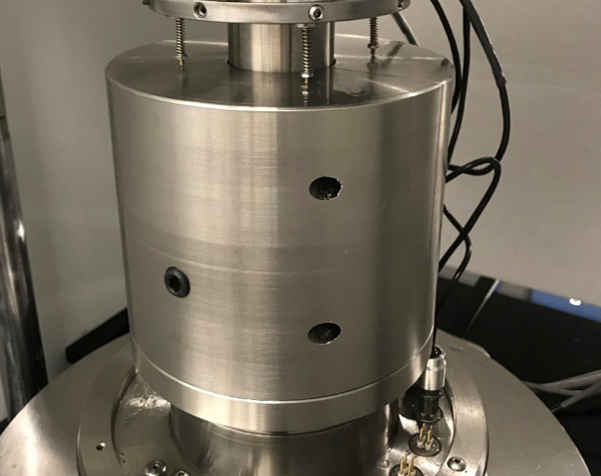

Interface mechanical testing (INF) is conducted to obtain hydraulic conductivity and shear strength of rock interfaces to determine their impact on hydraulic fracture propagation, fracture efficiency and height growth.

.png)

Fracture Connectivity (FCT) is performed to measure the loss of fracture aperture and/or fracture conductivity resulting from proppant embedment, proppant crushing, and the production of fines as the fracture is subjected to increasing compressive loads. An in-house designed testing configuration allows testing proppant packs greater than three layers and investigating rock-fluid-proppant interactions.

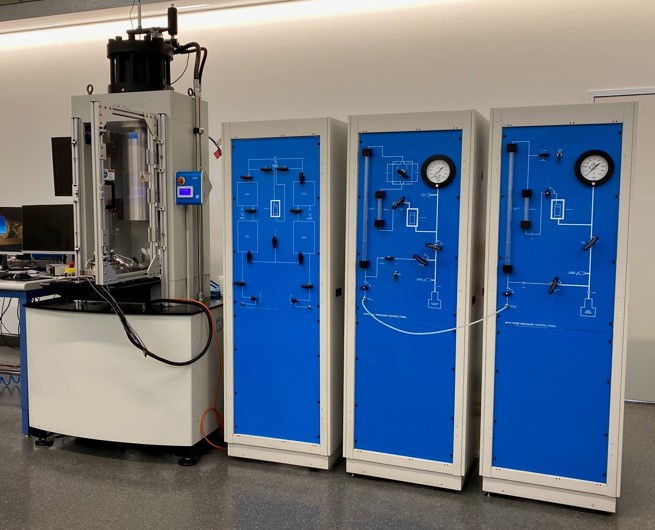

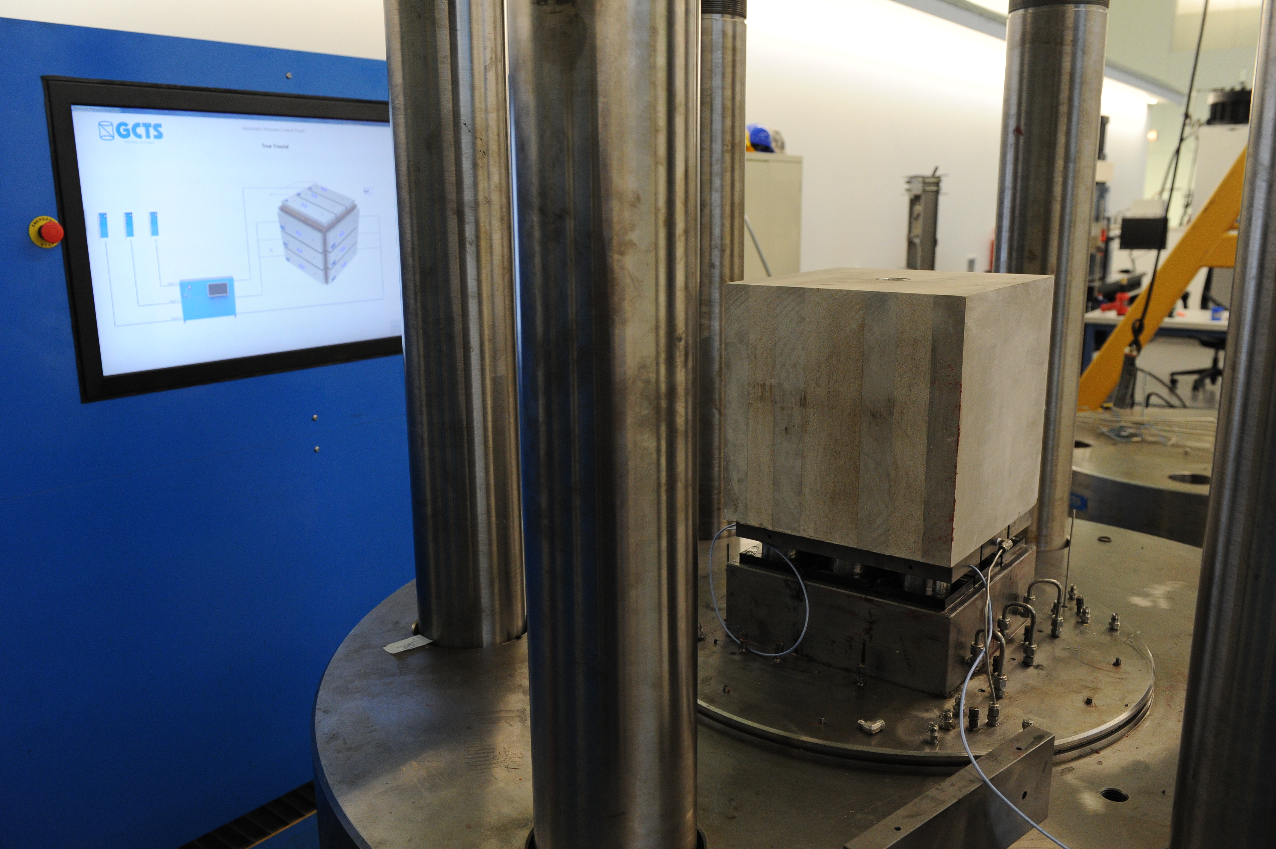

Large-scale polyaxial hydraulic fracturing testing (PFT) is conducted in a poly-axial stress frame (σ1 > σ2 > σ3) on outcrop rock samples under simulated conditions of in-situ stress to better understand the physics of hydraulic fracturing. Tests can be configured to simulate vertical or horizontal completions, cased or open hole completions, and using pressure ports, to identify the time at which fractures reach specific monitoring locations.

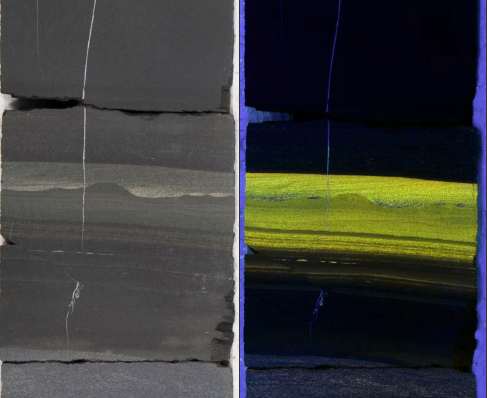

In unconventional shales, reservoirs are very heterogeneous, due to their deposition environment. Failure to take into account this charateristic on shale can have negative consequences. Interface Description aims to describe the layers that may negatively affect the drilling and fluid production of the well.